Ceramic brocade brick is also called mosaic

Refers to a variety of small ceramic tiles with a single side length of no more than 40mm

Combined into monochrome, spot, geometric pattern, etc

It is pasted on kraft paper or nylon mesh by the manufacturer

Ceramic tiles in one set

Ceramic brocade brick has good vitrification and high strength

It has good gas resistance and is full of decoration

It is used to lay the ground, anti-skid, wear-resistant, cheap, and high-quality

It is widely used in floor decoration of family toilets, toilets, and places with plenty of water

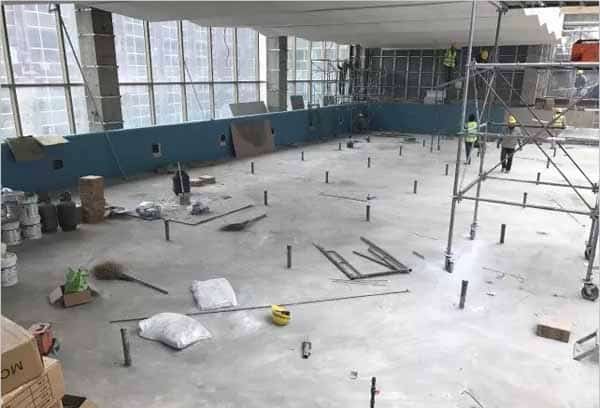

Let’s take a look at the whole construction process of pool mosaic today

Construction process

Base course treatment → sweeping cement mortar binding course → paving mosaic

→ corner joint repair → joint wiping and filling → maintenance

Base treatment

The smooth cement floor shall be roughened

Or brush interface treatment agent after washing

On oily ground

Brush with 10% caustic soda

Rinse with clean water

The pit shall be thoroughly washed and leveled with mortar

For the concrete rough base

Remove mortar skin and dust

And rinse it with clean water

The loose part of the base course shall be removed

Reinforcement shall be carried out after cleaning

For the pool

Also, do a good job in multi-layer waterproof

Sweep the plain cement slurry bonding layer

Sprinkle water evenly on the cleaned ground

Then evenly sprinkle 0.5 cement mortar with a broom

Or water group: 107 glue: water 1:0.1:4 polymer cement slurry

Paving ceramic brocade brick

The laid room shall be square

Pop up square vertical and horizontal lines on the leveling layer

Calculate the number of ceramic brocade tiles to be paved according to the construction detail drawing

If it is less than the whole sheet, it shall be thrown to the corner

The paper cutter can be used to pad the board and cut it into pieces of the required size

Strip paving with a half sheet or less than half sheet

To ensure that the quality of edges and corners is consistent with that of large-area surface course

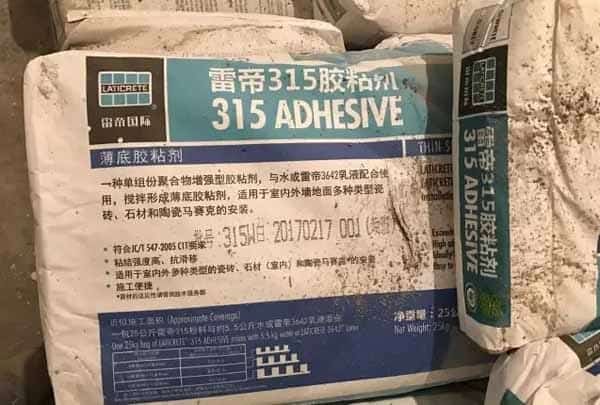

Lay ceramic brocade tiles with ceramic tile adhesive

From the inside out along the control line

(it can also be paved by throwing edges, and it can also be paved from the door when two rooms are connected)

Our swimming pool adopts the double-adhesive layer method

That is, scrape a layer of 2mm plain cement slurry or mortar on the wet leveling layer

At the same time, a layer of 1mm thick cement slurry is also scraped on the back of the ceramic brocade brick

All brick joints must be scraped full

Immediately snap the ceramic brocade brick to the specified position

Accurate and appropriate

After leveling, use a wooden clapboard to flatten and compact

And check the flatness and horizontal and vertical conditions at any time

Corner joint repair

When the whole room is paved

A large flat wooden board shall be padded on the brocade brick surface

So as to disperse the pressure on the brocade brick

The operator shall stand on the base plate and repair the surrounding corners

Repair the joint between the brocade brick floor and other floors

Ensure that the joints are straight and beautiful

Sewing

Timely check whether the gap is uniform

For unsmooth and unsmooth gaps

Use a small guiding rule to gently straighten and straighten the knife compared with the steel sheet

First, pull the vertical seam and then the horizontal seam

Then clap the brick surface with a hard clapboard

It shall be stitched, compacted, and leveled at the same time

In case of particle dropping, it shall be filled and glued immediately

Ceramic brocade tiles around floor drains and pipes shall be trial laid in advance

Cut it into proper shape with the nutcracker and lay it

Ensure that the connection of the pipe orifice is inlaid, consistent, and beautiful

The joint gap here shall not be greater than 5mm

After straightening the seam, gently sweep away the residual slurry on the surface

Caulking

The next day after jointing or after the final set of cement slurry bonding layer

Wipe the joint with plain cement slurry of the same color as ceramic brocade brick

Use cotton yarn to dip in at least the slurry and wipe the right seam from inside to outside

Or fill the joint with 1:2 fine sand cement slurry

Then, wipe the residual slurry on the brick

And sprinkle a layer of dry ash to thoroughly clean the surface

The ceramic brocade tile floor should be paved continuously in the whole room at one time

The joint pulling and cleaning shall be completed before the final set of the cement slurry bonding layer

Curing

After wiping the ceramic tile floor for 24h

It shall be cured at room temperature for 4 ~ 5D

Only when it reaches a certain strength can it be allowed to ascend

One Response

I need to to thank you for this good read!! I certainly loved every bit of it. I have you bookmarked to check out new stuff you postÖ